GE Supplies Subsea Production Systems for Troll

GE’s equipment is scheduled to be delivered in 2015.

GE Oil & Gas13/01/2014 18:37

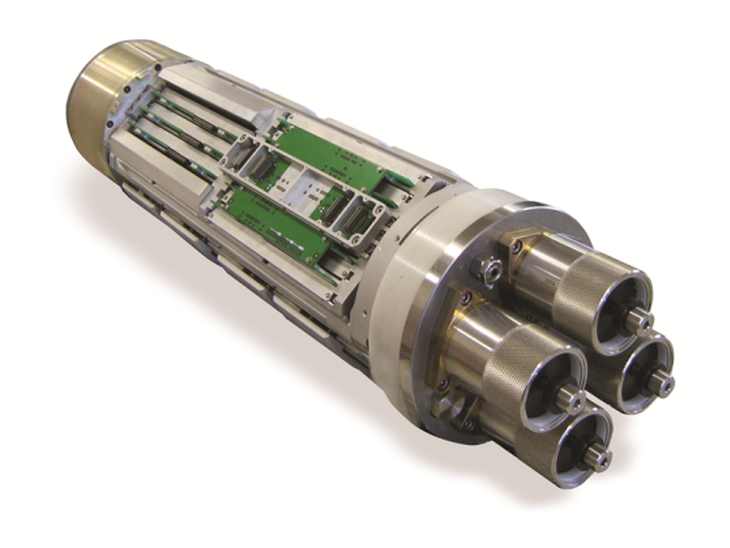

Demonstrating how GE technology helps operators extend the life of aging offshore production equipment, GE Oil & Gas is supplying Statoil Petroleum AS with its fifth generation SemStar5 Subsea Electronics Module to upgrade and extend the life of the subsea production control system for the Troll B field. GE Oil & Gas designed, built and installed the original Troll B subsea production system in 1995. The new Troll B subsea control system will upgrade all wells on manifolds D, E, F, G and H.

The award-winning SemStar5 will be designed to be backwards compatible with the existing system and will replace the reliable, but now obsolete technology that was provided originally. The SemStar5 offers architectural flexibility for a variety of production control system applications, and has successfully been deployed on several Statoil fields in recent years and has been field proven as a robust and reliable solution for upgrading subsea production control systems.

Featuring a modular design approach, SemStar5 is an example of the Industrial Internet’s role in boosting equipment efficiency and performance by providing the infrastructure that supports the higher bandwidth requirements of modern instrumentation while also offering high reliability. The modular design draws on GE’s nearly 30 years of experience with subsea systems. The first application of the new technology was for Statoil’s Tordis Vigdis Controls Modification project in the North Sea, west of Norway, in about 656 feet (200 meters) of water. Troll B was originally installed with a 20-year field life. Two decades later, GE is successfully maintaining the system on behalf of Statoil through its obsolescence management and active brownfield offerings.

“GE’s subsea production control system upgrade for Statoil underscores the important role that advanced and ultra-reliable controls technology can play in supporting new and existing offshore production projects,” said Tom Huuse, regional leader—Subsea Systems Services, Nordic Region for GE Oil & Gas. “GE’s Subsea Controls and Services team worked closely with Statoil for more than a year to offer its expertise and support Statoil in identifying the optimum, cost-effective solution that minimizes production downtime and provides an expandable controls solution for the future.”

In recent years operators have recognized the increased oil recovery opportunities in older fields by targeted technology insertion, and GE has responded to this need with an integrated support suite of offerings based on its leading edge technologies being installed in new green fields. Deployment of common modules and units such as the SemStar5 assure supportability and improved reliability and availability through the extended life of the field. This approach has been successfully validated on a number of projects already, and positions GE to be the brownfield controls supplier of choice for both GE and others’ legacy fields.

GE’s equipment is scheduled to be delivered in first half of 2015. The Troll B agreement also marks the latest of several equipment supply orders announced between the two companies in 2013. Based in Stavanger, Norway, Statoil Petroleum AS explores, produces and transports oil and gas including petroleum and petroleum-derived products. Statoil Petroleum AS is a subsidiary of Statoil ASA.

The Troll field is in the northern part of the Norwegian North Sea, around 40 mile (65 kilometers) west of Kollsnes, near Bergen. The license is operated by Statoil, (30.58 percent) and partners include Petoro (56 percent); Norske Shell (8.10 percent); Total E&P Norge (3.69 percent); and ConocoPhillips Skandinavia (1.62 percent).